How EPP Protects Defence Equipment in Harsh Conditions

Defence packaging today isn’t just about protection; it’s about ensuring equipment can move seamlessly from storage to deployment without losing performance. As mission cycles shorten and technology becomes more compact yet sensitive, the need for packaging that absorbs shock, resists climate extremes and maintains structural integrity has grown sharply. This shift has prompted militaries and OEMs to seek materials that not only comply with standards but also actively maintain equipment reliability in unpredictable and high-pressure conditions.

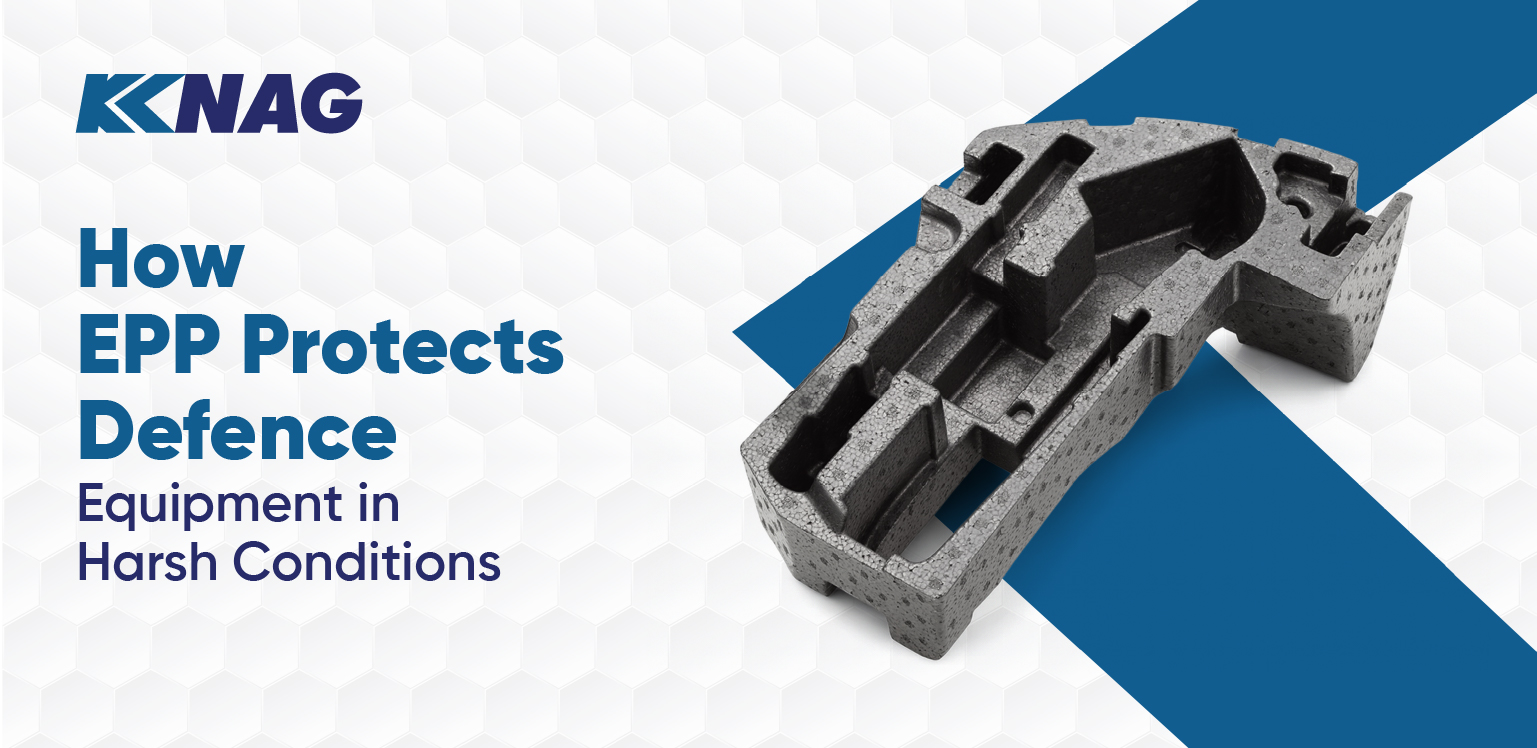

Among the materials currently used, Expanded Polypropylene (EPP) has proven to be one of the most adaptable for such applications. Its combination of high energy absorption, low density and thermal resilience makes EPP in defence packaging an increasingly common choice for both primary protection and reusable transit systems.

Table of Contents

- 01. Why Defence Packaging Demands Advanced Material Engineering

- 02. What Matters Most in Defence Packaging Materials

- 03. Applications of Expanded Polypropylene in Defence

- 04. Design Considerations for EPP in Defence Packaging

- 05. Comparing EPP with Other Military Packaging Materials

- 06. Sustainability in Defence Packaging Solutions

- 07. EPP’s Role in Future Defence Systems

- 08. Conclusion

Why Defence Packaging Demands Advanced Material Engineering

The defence sector presents unique challenges for packaging design. Systems are often deployed across environments ranging from arid deserts to humid coastlines or high-altitude cold regions. Packaging, therefore, must protect against:

- Mechanical shock and vibration during transport by air, road or sea.

- Abrasion and impact during field handling or repeated loading.

- Temperature extremes that can affect electronic calibration or battery performance.

- Ingress of moisture or fine dust that may damage precision components.

Traditional materials such as wood, aluminium and polyurethane foam meet some of these needs but fall short in areas like repeated impact recovery, moisture resistance and recyclability. Expanded polypropylene in defence applications addresses many of these gaps.

What Matters Most in Defence Packaging Materials

1. Energy absorption and resilience

EPP has a closed-cell structure that allows it to compress and recover without permanent deformation. When used in cases or as inserts, it absorbs repeated shocks during movement or deployment. This property is particularly valuable for sensitive optical or targeting devices that require precise calibration after transport.

2. Lightweight and portable

With a density significantly lower than solid plastics or metals, EPP helps reduce overall logistics weight. Lighter packaging translates to easier manual handling and lower transport energy consumption, which are key concerns in forward operating areas.

3. Environmental protection

Defence equipment requires packaging that performs reliably in demanding environments. Solutions must be engineered to withstand

significant temperature variations in field conditions, high humidity levels across coastal and tropical regions, fine dust, sand, saltwater and extended UV exposure during transport and deployment without degradation.

4. Compliance with military standards

All solutions must adhere to MIL-STD specifications and comply with globally recognised defence and quality benchmarks. This ensures that sensitive equipment remains protected, mission-ready and fit for long-term operational use.

5. Thermal insulation

EPP’s low thermal conductivity helps maintain controlled internal temperatures. This is important when packaging batteries, optical equipment or electronic modules that must not be exposed to sudden thermal shifts.

6. Durability and reusability

Unlike single-use foams, EPP maintains its mechanical strength through repeated deployment cycles. Many armed forces now specify reusable containers and inserts, aligning with sustainability goals and reducing total material throughput.

7. Design flexibility

EPP can be moulded into complex geometries with integrated handles, hinges or compartments. This adaptability allows engineers to develop durable EPP cases for weapons and instruments that combine protection with efficient space utilisation.

Applications of Expanded Polypropylene in Defence

1. Protective weapon cases

Rifles, sighting systems and ammunition often require tailored cavities for safe transport. EPP inserts support these designs while absorbing mechanical stress during drops or vibration.

2. Communication and control systems housing

Sensitive electronics such as transceivers, GPS units and sensors benefit from EPP’s anti-shock and anti-vibration characteristics.

3. Missile or drone component packaging

High-value composite structures or electronic payloads can be encased within multi-layer EPP housings for transport safety without adding excessive weight.

4. Field medical and diagnostic kits

Lightweight, insulated EPP containers keep medical instruments and temperature-sensitive supplies safe during rapid deployment.

5. Naval and marine equipment casings

Saltwater-resistant inserts and corrosion-proof equipment housings designed to safeguard navigation devices, communication gear and mission electronics during marine operations.

6. Field repair and tool kits

Custom‑moulded internal trays that keep tools, diagnostic instruments and replacement components organised and protected for rapid field servicing by maintenance teams.

Design Considerations for EPP in Defence Packaging

Designing effective EPP in defence packaging involves a structured engineering approach rather than material substitution. Key factors include:

- Load analysis and impact zones: Identifying critical stress areas and defining the required energy absorption capacity.

- Component securing method: Using moulded-in compartments or inserts to avoid relative motion between items.

- Stacking and dimensional stability: Ensuring that EPP’s compressive strength supports vertical stacking during long storage periods.

- Surface finish: Selecting smooth or textured surfaces depending on cleaning and identification needs.

- Integration with external shells: In many designs, EPP is used as an internal core within rotationally moulded outer shells to provide multi-layer protection.

Through correct design, EPP can complement rather than replace other materials, resulting in hybrid systems that balance protection, weight and cost efficiency.

Comparing EPP with Other Military Packaging Materials

| Property | EPP | PU Foam | Aluminium | Wood |

|---|---|---|---|---|

| Impact Resistance | Excellent | High | Good but rigid | Moderate |

| Weight | Very light | Light | High | High |

| Reusability | Excellent | Low | High | Low |

| Moisture Resistance | Excellent | Low | Moderate | Poor |

| Thermal Insulation | Moderate | High | Low | Low |

| Recyclability | Excellent | Poor | Good | Limited |

This comparison highlights why Expanded Polypropylene in defence has gained acceptance across global supply programmes. It provides a unique blend of performance, reusability and environmental responsibility, aligning with current military procurement trends.

Sustainability in Defence Packaging Solutions

Beyond technical performance, EPP supports long-term sustainability objectives. Its closed-loop recyclability enables defence organisations to reclaim and reuse the material at end-of-life. Lower weight also reduces carbon output during logistics. These advantages position EPP among the best materials for military packaging, where both endurance and environmental accountability matter.

EPP’s Role in Future Defence Systems

The evolving defence ecosystem emphasises modularity, rapid deployment and reduced maintenance. As mission equipment becomes more compact and electronically integrated, packaging will need to balance protection with thermal and electromagnetic considerations. EPP’s ability to integrate with other materials, its stable mechanical performance and its reusability will continue to make it a strategic choice for defence packaging engineers.

Conclusion

From military packaging materials for electronics to durable EPP cases for weapons, the use of Expanded Polypropylene in defence represents a shift towards smarter, more efficient protection. All its properties help safeguard mission-critical equipment while supporting circular use within supply systems. In the demanding world of defence logistics, EPP continues to prove that effective protection does not have to come at the cost of weight, waste or complexity.